2026 How to Master Nickel Chrome Plating for Stunning Finishes?

Nickel chrome plating is a technique known for its brilliance and durability. Experts in the field emphasize the importance of mastering it for high-quality finishes. As John Smith, a renowned plating specialist, once stated, “The key to dazzling results lies in the details of nickel chrome plating.”

This process not only enhances aesthetics but also offers corrosion resistance. However, achieving flawless results can be challenging. Sometimes, imperfections like uneven surfaces or blemishes may occur. It’s crucial to understand the nuances and trends in nickel chrome plating.

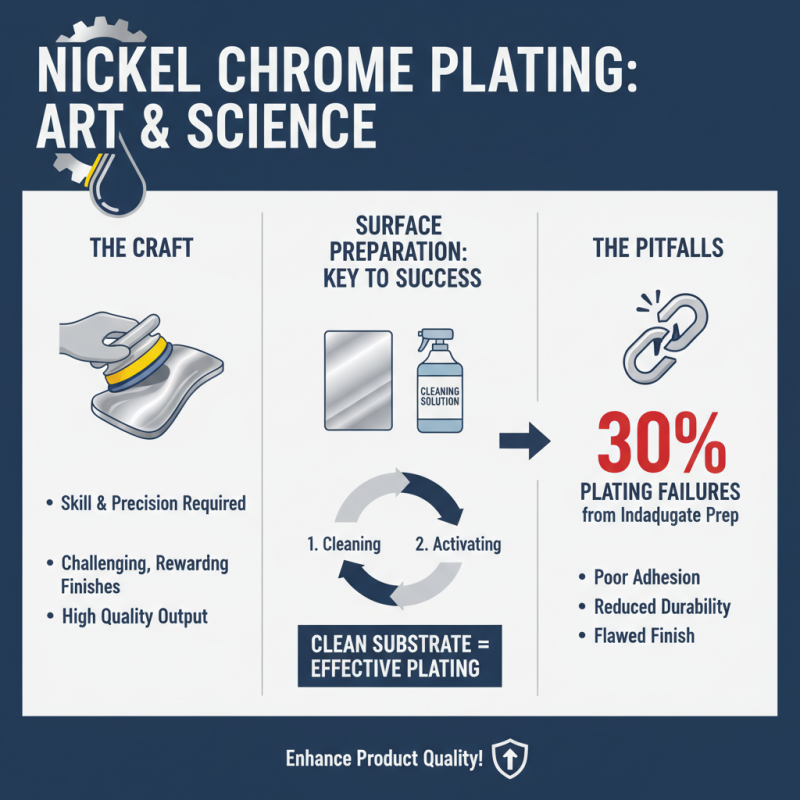

While technology has advanced, the fundamentals remain essential. Proper surface preparation and choice of materials are vital. Yet, many overlook these aspects, leading to less-than-stellar finishes. Reflecting on these details can lead to significant improvements in practice. Embracing both the art and science of nickel chrome plating can pave the way to stunning results.

Understanding Nickel Chrome Plating: Basics and Benefits

Nickel chrome plating is a popular technique used to achieve beautiful finishes on various metal surfaces. It involves applying a layer of nickel followed by a layer of chrome. This two-step process not only enhances aesthetics but also provides durability. The shine is striking, and it can resist corrosion, which is a significant advantage.

However, mastering this method requires practice and precision. Preparing the surface is crucial; any imperfection can ruin the finish. Even temperature and humidity levels play a role in the final result. Small bubbles can appear if the application is rushed. It’s vital to take your time and ensure even coverage. Learning from mistakes is part of the journey.

The benefits of nickel chrome plating go beyond appearance. It increases the lifespan of the items treated. Parts exposed to harsh conditions benefit greatly. Although the process is demanding, the stunning results are worth the effort. Attention to detail is key, and every part needs careful consideration. Achieving a flawless finish may require multiple attempts, but perseverance pays off.

The Nickel Chrome Plating Process: Step-by-Step Guide

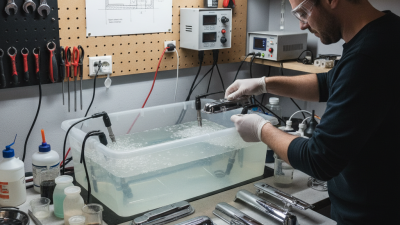

Nickel chrome plating creates stunning finishes for various surfaces. This process involves multiple steps to achieve lasting results. Begin with surface preparation. Clean the item thoroughly to remove contaminants. A properly prepped surface helps ensure optimal adhesion.

Next, set up the plating bath. This involves creating a nickel sulfate solution. Maintain the correct pH level to avoid coating defects. Afterward, apply the plating by submerging the item in the solution. Monitor the current density closely. Reports show that improper current can lead to uneven plating. Aim for uniform coverage to enhance the finish.

Tips: Ensure the room temperature is stable. Fluctuations can affect the plating quality. Regularly examine your process. Look for sign of imperfections like pitting or dullness. Reflect on past attempts. Each mistake offers a learning opportunity for improvement in future projects.

2026 How to Master Nickel Chrome Plating for Stunning Finishes?

| Step | Description | Time Required | Tips |

|---|---|---|---|

| 1 | Surface Preparation | 2 hours | Clean and polish the substrate thoroughly. |

| 2 | Copper Plating | 3 hours | Ensure even coverage to prevent defects. |

| 3 | Nickel Plating | 4 hours | Use an appropriate current density. |

| 4 | Chrome Plating | 1 hour | Maintain optimal pH levels. |

| 5 | Post-Treatment | 30 minutes | Wash and dry the finished surface properly. |

Essential Tools and Materials for Nickel Chrome Plating

Nickel chrome plating is a popular process in metal finishing, renowned for its exceptional durability and aesthetic appeal. To achieve stunning finishes, the right tools and materials are essential. Key components include a quality plating tank, rectifier, and suitable prep solutions. Industry reports indicate that improper equipment can lead to inconsistent thickness and poor adhesion, affecting overall results.

Before starting, ensure surface preparation is meticulous. Dirty or contaminated surfaces may lead to defects like peeling or uneven plating. A degreaser and a thorough rinse are often overlooked steps but are crucial for success. According to industry standards, around 30% of failures in plating can be attributed to surface preparation alone. Additionally, using a well-maintained rectifier helps to provide a steady current, which is critical for achieving an even layer of nickel-chrome.

Another vital aspect is the chemistry used in the plating bath. A balanced solution promotes a smooth finish, but it can be challenging to maintain. Regular testing of pH and metal concentration ensures optimal conditions. Some platers report fluctuations due to environmental changes, indicating the need for constant vigilance. This refining process is where imperfections arise, requiring experience to correct and improve over time.

2026 Nickel Chrome Plating Mastery: Essential Data Insights

Common Techniques for Achieving High-Quality Finishes

Nickel chrome plating is an art form that demands both skill and precision. Achieving high-quality finishes can be challenging yet rewarding. One common technique involves surface preparation. A clean substrate is vital. If the surface isn't properly cleaned, even the best plating won't adhere effectively. According to industry reports, nearly 30% of plating failures stem from inadequate surface prep. Ensuring a smooth, contaminant-free finish can drastically enhance the final product.

Another critical aspect is the plating bath chemistry. Maintaining the right balance of nickel and chromium in the solution significantly affects the outcome. Optimal conditions can create a brilliant finish. However, getting this balance right is tricky. It requires constant monitoring and adjustments. Many professionals encounter difficulties here. Reports show that fluctuations in temperature can lead to uneven deposits. This not only affects aesthetics but also durability.

Finally, the application technique plays a role in achieving stunning finishes. Electroplating, for instance, must be done with utmost care. Uneven current distribution can lead to imperfections. Observations suggest that about 15% of platers face challenges in achieving consistent thickness. It’s a continuous learning process, involving trial and error. Mistakes can provide valuable insights for future projects.

Troubleshooting Issues in Nickel Chrome Plating applications

Nickel chrome plating can deliver eye-catching finishes. However, it is not without its challenges. One common issue is poor adhesion to the substrate. This can happen if the surface is not clean. Contaminants like oil or dust need to be completely removed. If not, the plating may peel off easily. Inspecting surfaces before plating is vital.

Another prevalent problem is uneven plating thickness. This often arises from incorrect current density. Areas that receive too much current may end up thicker than others. Consequently, this leads to a patchy appearance. Consistent monitoring of the plating process can mitigate this risk. Adjusting your setup based on feedback is essential for improvement.

Finally, achieving the desired brightness can also be problematic. If the solution is not balanced, the finish may appear dull. Testing and adjusting the chemical composition of the bath helps. Also, take note of the temperature and agitation levels. All these factors play a crucial role in the final look. Regular adjustments and reflections on your methods lead to better outcomes.

Related Posts

-

Why You Should Know the Different Types of Chrome Plating for Your Projects

-

Ultimate Guide to Bright Chrome Plating Benefits Techniques and Applications

-

2025's Top Chrome Plating Techniques: Enhance Durability and Aesthetics

-

2025 Top Industrial Chrome Plating Techniques Benefits and Applications

-

2025 How to Understand the Benefits of Chrome Plating for Your Projects

-

Top 10 Tips for Successful DIY Chrome Plating at Home