2025 How to Understand the Benefits of Chrome Plating for Your Projects

In the evolving landscape of manufacturing and design, the benefits of chrome plating have emerged as a pivotal consideration for engineers and project managers alike. According to a recent report by the International Chrome Plating Association, the chrome plating market is projected to reach $20 billion by 2025, driven largely by its superior corrosion resistance and aesthetic appeal. These factors not only enhance the longevity of products but also elevate their market value. As renowned plating expert Dr. William Harper emphasizes, "Chrome plating is not merely a finishing touch; it is an essential process that significantly extends the lifespan and functionality of components used across various industries."

As designers and manufacturers strive for competitive advantages, understanding the benefits of chrome plating becomes paramount. This electroplating technique offers numerous advantages, including improved surface hardness and reduced friction, which translate to enhanced performance in automotive, aerospace, and industrial applications. Furthermore, the reflective quality of chrome plating adds a visual appeal that can set products apart in crowded markets. With these strengths, projects that incorporate chrome plating can achieve not only improved durability but also greater aesthetic and functional value, making it a vital consideration in modern production strategies.

Understanding Chrome Plating: Definition and Process Overview

Chrome plating is a popular finishing process that involves applying a thin layer of chromium to a surface to enhance its appearance and durability. This process typically starts with surface preparation, where the base material is cleaned and polished to remove any imperfections. Following this, the object is placed in a plating solution containing chromium ions, and an electric current is applied. This current facilitates the deposition of chromium onto the surface, resulting in a shiny, reflective finish that is highly resistant to corrosion and wear.

When considering chrome plating for your projects, it's essential to keep a few tips in mind. First, assess the base material of your project carefully; not all materials are suitable for plating. Metals such as steel, aluminum, and brass generally offer good results. Second, think about the thickness of the chrome layer you desire. Thicker layers provide better durability but may also increase costs and affect the time required for completion. Lastly, always consult with a professional platers to discuss your specific needs and obtain guidance on any potential complications during the plating process.

By understanding the definition and process of chrome plating, you can make more informed decisions that will not only enhance the aesthetic appeal of your projects but also extend their lifespan.

Understanding the Benefits of Chrome Plating for Your Projects

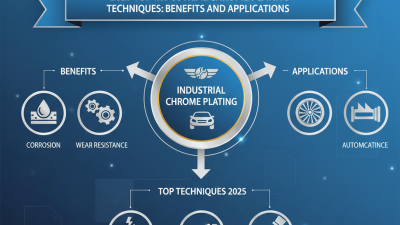

Key Benefits of Chrome Plating for Various Projects

Chrome plating offers numerous advantages for various projects, making it an appealing choice for both industrial and decorative applications. One of the key benefits is enhanced durability; chrome plating creates a tough outer layer that protects surfaces from wear, corrosion, and abrasion. This means that components can withstand harsh environmental conditions, ultimately extending their lifespan and reducing the need for frequent replacements. Additionally, the shiny finish of chrome adds aesthetic value, making it a popular option in automotive, furniture, and appliance design, where visual appeal is crucial.

Another notable benefit of chrome plating is its low friction properties, which significantly improve the performance of moving parts. By reducing drag between surfaces, chrome-plated components can operate more efficiently, which is especially beneficial in machinery and equipment requiring precision. Furthermore, chrome plating is relatively easy to maintain; it resists tarnishing and rust, allowing surfaces to maintain their luster over time with minimal effort. This combination of functionality and aesthetics makes chrome plating a versatile solution for enhancing the quality and performance of various projects across multiple industries.

Comparing Chrome Plating to Other Finishing Techniques

When considering various finishing techniques for your projects, chrome plating stands out due to its unique blend of aesthetic appeal and functional benefits. Unlike traditional finishes such as paint or powder coating, chrome plating provides a reflective, mirror-like surface that enhances the visual quality of the object while also offering superior resistance to corrosion and wear. This makes chrome plating an ideal choice for applications where both appearance and durability are essential, particularly in automotive and decorative applications.

In comparison to other techniques like anodizing or galvanizing, chrome plating offers a distinct advantage in terms of glossiness and ease of cleaning. While anodizing provides a protective oxide layer on aluminum surfaces, it typically lacks the high shine associated with chrome. Additionally, galvanizing, although effective in preventing rust, can impart a more industrial look that may not be suitable for all projects. Chrome plating not only elevates the aesthetic but also helps in reducing friction and improving the longevity of the components, thereby making it a preferred choice for designers and engineers aiming for high performance and visual appeal.

2025 How to Understand the Benefits of Chrome Plating for Your Projects - Comparing Chrome Plating to Other Finishing Techniques

| Finishing Technique | Durability | Corrosion Resistance | Aesthetic Appeal | Application Cost |

|---|---|---|---|---|

| Chrome Plating | High | Excellent | Highly Reflective | Moderate |

| Powder Coating | Moderate | Good | Varied Colors | Low |

| Anodizing | Moderate | Very Good | Matte Finish | Moderate |

| Electroplating | Good | Fair | Shiny Finish | High |

Applications of Chrome Plating in Different Industries

Chrome plating is a versatile process that finds applications across various industries due to its ability to enhance both aesthetic appeal and functional properties of products. In the automotive industry, for example, chrome plating is widely used for bumpers, grille components, and wheels. According to a report by MarketsandMarkets, the automotive chrome plating market is expected to grow at a CAGR of 5.1% from 2020 to 2025, reflecting the continuous demand for both performance and visual enhancements in vehicles.

In the aerospace sector, chrome plating is essential for components subjected to extreme conditions, providing improved corrosion resistance and reducing friction. A study by Grand View Research indicates that the aerospace coatings market is expected to reach USD 42.2 billion by 2025, with chrome plating playing a crucial role in maintaining performance standards and durability in various aircraft components.

Tips: When considering chrome plating for your project, it’s vital to assess the specific needs of your application. Ensure that the thickness of the chrome layer is suitable for the operational environment, as this can significantly affect the longevity of the finish. Additionally, factor in the costs associated with maintenance and potential re-plating to ensure the most cost-effective solutions for your needs.

Factors to Consider When Choosing Chrome Plating for Your Project

When choosing chrome plating for your project, several key factors should be carefully considered to ensure optimal results. Firstly, the substrate material plays a critical role in determining the effectiveness of the chrome plating process. Different metals, like steel or aluminum, have varying compatibility with chrome plating. It's important to assess the substrate's surface condition and prepare it adequately, as any imperfections can affect the adhesion and durability of the chrome layer.

Another significant factor is the intended use of the plated object. Projects that require enhanced corrosion resistance or aesthetic appeal may benefit from thicker chrome layers, while applications prioritizing tool performance might need a different finish. Additionally, the environmental conditions the final product will face—such as exposure to moisture or chemicals—should be evaluated. Understanding these requirements will guide you in selecting the right type of chrome plating, whether it be decorative or hard chrome, ensuring that your project meets its functional and visual goals effectively.

Related Posts

-

Why You Should Know the Different Types of Chrome Plating for Your Projects

-

Ultimate Guide to Bright Chrome Plating Benefits Techniques and Applications

-

2025's Top Chrome Plating Techniques: Enhance Durability and Aesthetics

-

2025 Top Industrial Chrome Plating Techniques Benefits and Applications

-

Top 10 Uses of Chromium in Electroplating You Need to Know

-

2025 Top Guide to Cobalt Plating Techniques and Applications